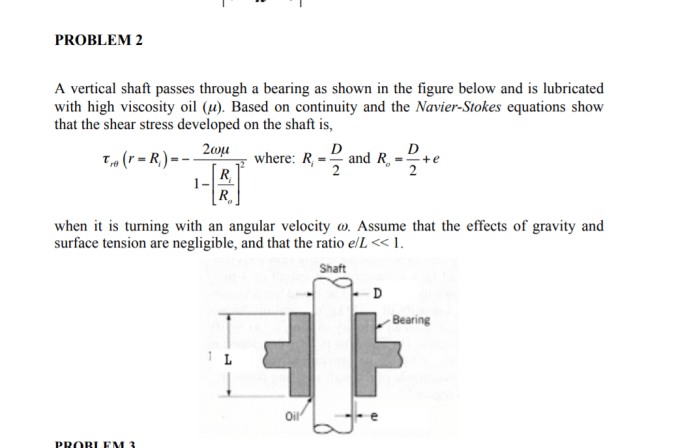

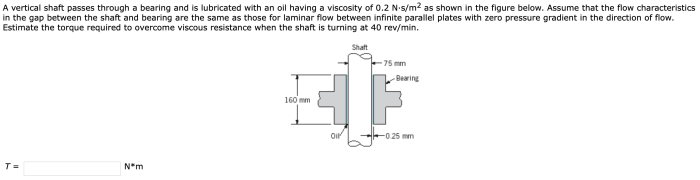

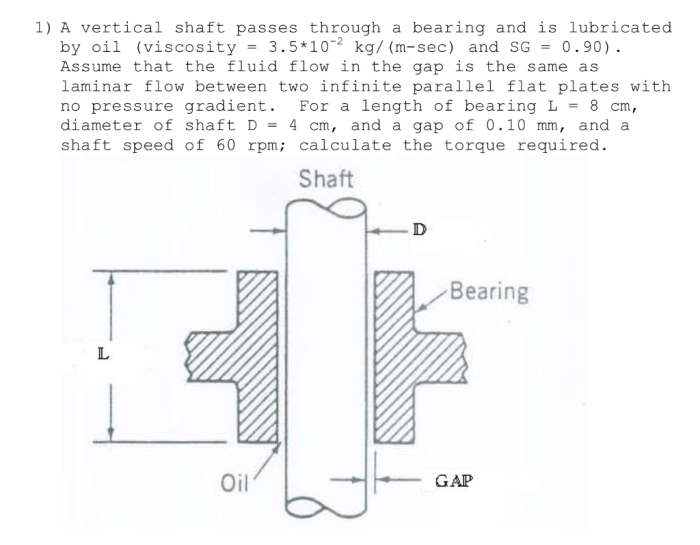

A vertical shaft passes through a bearing and is lubricated – In the realm of mechanical engineering, a vertical shaft passing through a bearing plays a crucial role in transmitting motion and supporting loads. Lubrication is paramount in this context, ensuring smooth operation, reducing wear and tear, and extending the lifespan of the system.

This article delves into the intricacies of vertical shaft lubrication, exploring various bearing types, lubrication methods, and lubricant properties.

1. Introduction

A vertical shaft is a rotating shaft that is oriented vertically. Bearings are used to support vertical shafts and reduce friction. Lubrication is essential for vertical shaft bearings to prevent wear and extend their service life.

2. Types of Bearings

Various types of bearings are used with vertical shafts, including:

- Plain bearings: Simple bearings that consist of a shaft rotating within a sleeve or bushing.

- Rolling element bearings: Bearings that use rolling elements, such as balls or rollers, to reduce friction.

- Hydrodynamic bearings: Bearings that use a fluid film to support the shaft and reduce friction.

- Hydrostatic bearings: Bearings that use an external pump to create a fluid film to support the shaft.

3. Lubrication Methods

Vertical shaft bearings can be lubricated using various methods, including:

- Oil bath lubrication: The bearing is submerged in an oil bath, which provides continuous lubrication.

- Grease lubrication: Grease is applied to the bearing, which provides lubrication for a longer period of time than oil.

- Circulating oil lubrication: Oil is circulated through the bearing, which provides continuous lubrication and cooling.

4. Lubricant Properties

Lubricants suitable for vertical shaft bearings should possess certain properties, including:

- Viscosity: The ability of the lubricant to resist flow.

- Film strength: The ability of the lubricant to form a protective film between the shaft and the bearing.

- Corrosion protection: The ability of the lubricant to prevent corrosion of the shaft and the bearing.

5. Lubrication System Design

When designing a lubrication system for vertical shafts, factors to consider include:

- Shaft speed: Higher shaft speeds require a lubricant with higher viscosity.

- Load: Heavier loads require a lubricant with higher film strength.

- Environmental conditions: Extreme temperatures or corrosive environments require a lubricant with special properties.

6. Monitoring and Maintenance

To ensure optimal operation of vertical shaft lubrication systems, it is important to monitor their performance and perform regular maintenance. Monitoring techniques include:

- Temperature monitoring: Monitoring the temperature of the bearing to detect excessive friction or wear.

- Vibration monitoring: Monitoring the vibration of the bearing to detect imbalances or misalignment.

- Oil analysis: Analyzing the oil to detect the presence of wear particles or contaminants.

7. Troubleshooting

Common problems associated with vertical shaft lubrication include:

- Insufficient lubrication: Can lead to excessive wear and bearing failure.

- Contaminated lubricant: Can cause damage to the shaft and the bearing.

- Improper bearing alignment: Can cause uneven wear and premature bearing failure.

FAQ Corner: A Vertical Shaft Passes Through A Bearing And Is Lubricated

What is the primary purpose of lubrication in vertical shaft applications?

Lubrication reduces friction between the shaft and the bearing, minimizing wear and tear. It also dissipates heat generated by friction, preventing overheating and premature failure.

What factors should be considered when selecting a lubricant for a vertical shaft?

Factors to consider include the shaft speed, load, operating temperature, and environmental conditions. The lubricant’s viscosity, film strength, and anti-wear properties must be carefully matched to the application.

How can proper lubrication extend the lifespan of a vertical shaft system?

Proper lubrication reduces friction and wear, preventing premature failure of the shaft and bearings. It also protects against corrosion and contamination, ensuring optimal performance and longevity.