Lupo corporation uses a job-order costing system – Lupo Corporation, a leading manufacturer of specialized equipment, has implemented a job-order costing system to effectively manage and assign costs to individual production jobs. This system enables Lupo Corporation to accurately track and analyze costs, ensuring profitability and informed decision-making.

Job-order costing is a method of accumulating and assigning costs to specific jobs or production orders. It is commonly used in industries where products are manufactured or services are provided on a customized basis, such as construction, engineering, and printing.

1. Job-Order Costing System Overview

Job-order costing is a cost accounting system used to accumulate and assign costs to specific jobs or production orders. It is commonly employed in industries where products are manufactured or services are provided on a customized or project-based basis.

Key Characteristics of a Job-Order Costing System

- Costs are accumulated for each individual job or production order.

- Jobs are tracked throughout the production process, from raw materials to finished goods.

- Costs are assigned to jobs based on direct material, direct labor, and indirect manufacturing costs.

Examples of Industries That Commonly Use Job-Order Costing

- Construction

- Engineering

- Printing

- Furniture manufacturing

- Custom machinery

2. Lupo Corporation’s Job-Order Costing System

Lupo Corporation uses a job-order costing system to track costs associated with its custom-built machinery production.

Cost Accumulation and Assignment

Lupo Corporation accumulates direct material costs by tracking the materials used for each job. Direct labor costs are assigned based on the hours worked on each job by production employees. Indirect manufacturing costs, such as overhead expenses, are allocated to jobs using a predetermined overhead rate.

Advantages and Disadvantages

Advantages:

- Provides detailed cost information for each job.

- Facilitates accurate job pricing and profitability analysis.

- Helps identify areas for cost reduction and process improvement.

Disadvantages:

- Can be complex and time-consuming to implement and maintain.

- May not be suitable for high-volume production environments.

- Requires accurate data collection and allocation methods.

3. Cost Accumulation and Assignment: Lupo Corporation Uses A Job-order Costing System

Direct Material Costs

Lupo Corporation uses a perpetual inventory system to track direct material costs. As materials are issued to production, their costs are charged to the appropriate job.

Indirect Manufacturing Costs

Lupo Corporation allocates indirect manufacturing costs to jobs based on a predetermined overhead rate. This rate is calculated by dividing the estimated total indirect manufacturing costs for the period by the estimated total direct labor hours for the period.

Importance of Accurate Cost Accumulation and Assignment

Accurate cost accumulation and assignment are crucial for effective job costing. They ensure that the costs of each job are correctly determined, allowing for accurate pricing, profitability analysis, and decision-making.

4. Job Costing Reports and Analysis

Lupo Corporation generates various job costing reports to monitor job profitability and make informed decisions.

Types of Job Costing Reports

- Job cost sheets

- Job summary reports

- Profitability reports

- Variance reports

Use of Job Costing Reports

- Monitor the progress of jobs and identify potential cost overruns.

- Analyze the profitability of individual jobs and product lines.

- Evaluate the efficiency of production processes and identify areas for improvement.

5. Challenges and Considerations

Challenges Faced by Lupo Corporation

- Maintaining accurate cost data.

- Allocating indirect manufacturing costs fairly.

- Adapting the job-order costing system to changing business needs.

Importance of Continuous Improvement, Lupo corporation uses a job-order costing system

Lupo Corporation continuously evaluates and improves its job-order costing system to ensure its effectiveness and alignment with business objectives.

Recommendations for Enhancing Effectiveness

- Implement a robust data collection system.

- Review and update overhead allocation rates regularly.

- Train employees on the importance of accurate cost reporting.

- Use job costing reports to identify areas for cost reduction and process optimization.

FAQ Explained

What are the key advantages of using a job-order costing system?

Job-order costing provides accurate cost information for individual jobs, enabling better decision-making regarding pricing, resource allocation, and production efficiency.

How does Lupo Corporation accumulate direct material costs?

Lupo Corporation uses a perpetual inventory system to track direct material costs. As materials are issued to production, their costs are charged to the specific job orders.

What methods does Lupo Corporation use to allocate indirect manufacturing costs?

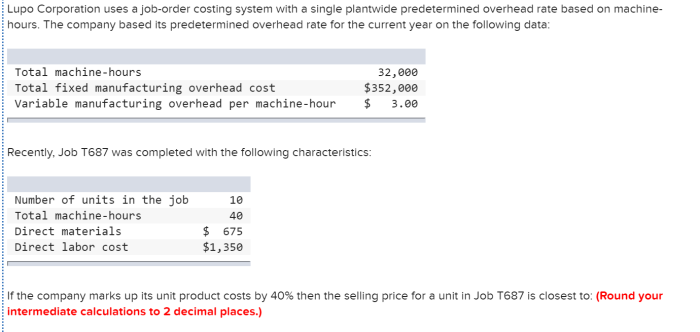

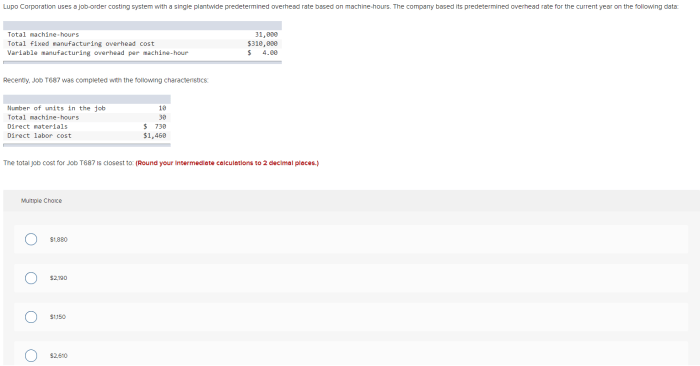

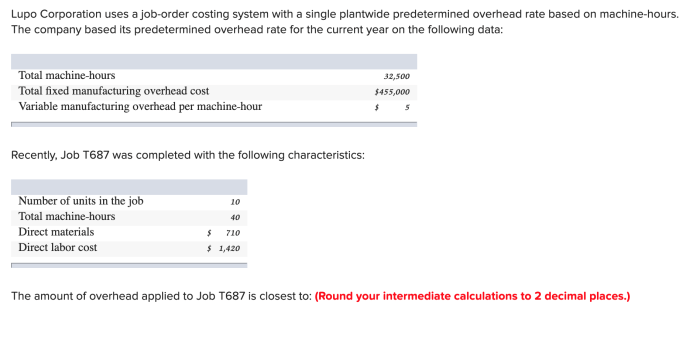

Lupo Corporation uses a predetermined overhead rate based on machine hours to allocate indirect manufacturing costs to individual jobs.